Abby’s Guide > Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) > Discussions > Single stage output velocity

Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) Discussions |

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Single stage output velocity

Original Message Jan 31, 2012 2:27 pm |

|

Horizontal lists don't usually post correctly so the info below..... Make...............Engine RPM,,,,,,Auger dia........Auger RPM................Velocity out ft/min Powerlite, .........4000....................7........................1550..............................2840 Murray 3ph........4100..................8 1/4....................1025..............................2213 Maco 3hp...........4100..................8 1/4....................980...............................2116 Borat....................6000.................8 1/4...................1470.............................3173 Toro 350..............4200.................8 1/2.....................xxxxx..............................xxxxx Borat, Your auger RPM was approximated from Maco's. Different belts but likely both pulley diameters are the same or very close. The estimate was 245 RPM per 1K engine RPM. It would be interesting to compare impeller bearings. Murray and Maco both have roller bearings in the drive side of the auger shaft, flange on the other. Borat your's is probably the same. I'd have to check the Toro but I think flange on both sides. The velocity out of a dual stage is 3400 to 4000 ft/min most common around 3700-3800 ft/min (that is if I am remembering those numbers right). The better brands of machines will all be at the top of the high end. Those numbers seem about right given what a Powerlite can do versus a dual stage in the back yard in conditions good for the Powerlite.

This message was modified Feb 1, 2012 by trouts2

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #13 Feb 1, 2012 3:17 pm |

|

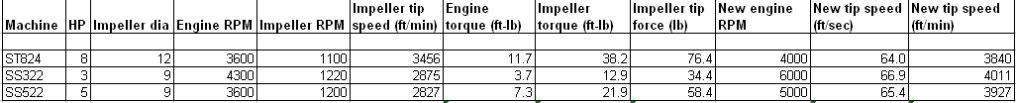

hirschallan, you're probably right. And, from what trouts2 posted, the torque is already dropping off. The benefit would be that, even if you're past the torque peak, the impeller & auger will be spinning faster, and will better deal with lightweight snow. They'll fling more, and further. And as the engine loads up, it will slow down anyhow, more towards the normal operating speed. trouts2, I like that idea, of adjusting full throttle to be past 3600, for when you need just a bit more. Then just drop the throttle slightly for normal operation. Simple yet clever  I updated my numbers, to change everything to ft/min, from ft/sec. I also added a column which might begin to address aa335's point about the weight of the snow. I took the engine's RPM and rated HP, and calculated engine torque from that. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. It completely ignores power being used actually turning the augers themselves (on a 2-stage) and driving the wheels, in addition to other losses. It was more just for curiosity, and to get a relative understanding of how well the impeller/paddle would deal with heavier snow. The "Impeller tip force" would relate best to heavy snow performance, in my opinion. It's worth the paper it's printed on, as long as you don't print it   |

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #14 Feb 2, 2012 3:16 am |

|

Red, A few questions for you. >>>I took the engine's RPM and rated HP, and calculated engine torque from that. Makers usually give a Max torque at some rpm and that is usually below max torque say 24-2800 on a 3600 engine. If you take max rpm and the makers max torque that won’t be the same as the makers max torque as they spec max at some rpm lower than max. At least that’s what I’ve always seen. Also, I think hp figures are at max rpm not at max torque rpm. Since torque drops off faster and faster after max heading to 3600 and those curves vary from engine to engine then using max at 3600 can’t be done. It’s non-linear and rate of torque drop off different from engine to engine. I suppose it’s a pickle for makers. If they gave ratings at 3600 people could compare levels vs makers given max torque at 24, 25, 2600…& etc. But that would not give you max which is good to know for apps where the engine sags under load into it’s power torque range like in snowblowers. In the past I’ve looked at trying to figure out what the torque curve would be for a pushed engine and was unable to come up anything. If you have a makers published power curve then OK but most don’t give them. If the above is right then it would make the impeller torque and lb force figures iffy. But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? Just say the torque figures are off but are a rough ball park. If they are close enough then useful even if inaccurate. It’s a little more understandable to compare lbs than torque numbers. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. As mentioned before, as a side issue when thinking about this stuff it’s one thing to have the numbers but the total design implementation factors in. Once you have the get force there’s the design of the barrel, the impeller arm count, the shape of the impeller arms, shape of the bucket outlet hole, chute shape and a many more. Over the years other than chute shape a have not made much progress on understanding the other parts especially the shape of the impeller arms. It’s pretty much black magic but basic to is all is the umph has be there. Nice chart. If the chart is in excel and you don’t mind please send me a copy, trouts2@gmail.com

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #15 Feb 2, 2012 4:31 am |

|

Makers usually give a Max torque at some rpm and that is usually below max torque say 24-2800 on a 3600 engine. <snip>

If the above is right then it would make the impeller torque and lb force figures iffy. But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? Just say the torque figures are off but are a rough ball park. If they are close enough then useful even if inaccurate. It’s a little more understandable to compare lbs than torque numbers. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. As mentioned before, as a side issue when thinking about this stuff it’s one thing to have the numbers but the total design implementation factors in. Once you have the get force there’s the design of the barrel, the impeller arm count, the shape of the impeller arms, shape of the bucket outlet hole, chute shape and a many more. Over the years other than chute shape a have not made much progress on understanding the other parts especially the shape of the impeller arms. It’s pretty much black magic but basic to is all is the umph has be there. Nice chart. If the chart is in excel and you don’t mind please send me a copy, trouts2@gmail.com You're right. However, I made no effort to use manufacturer's torque numbers (which are typically harder to find for older, hp-rated engines anyhow). If we assume that the horsepower of the engine is rated based on the operating speed (a fair assumption), then this works better. You can calculate torque if you know hp and RPM, which is what I did, for the operating speeds listed. Now, in the case of the SS322, the operating speed is 4300, not 3600. I don't know which speed the 3hp is based on. But I used the 4300, for discussion purposes. You're right that the torque is definitely a curve, so this number doesn't exactly tell the whole story. But there are so many other assumptions involved in this anyhow that it almost doesn't matter  I have come across a torque/power curve plot for at least 1 engine, I'd have to look later and see if I saved it. " But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? "

Torque is commonly listed in ft-lb (well, lb-ft, really, but that's kind of semantics). A torque of 5 ft-lb can apply a force of 5 lbs (can lift 5 lbs), at a radius of 1 ft. Or 2.5 lbs at a radius of 2 ft. So, in the example of the ST824, the impeller has a 12" diameter, or 6" radius (0.5 ft). So the maximum force at the tip is torque/radius, or 38.2 ft-lb / 0.5 ft, or 76.4 lb.

So given the same torque on a 12" diameter impeller vs an 8" diameter impeller, the max tip force will be greater on the smaller-diameter, 8" impeller. It will slow down less with heavy snow. But it also won't be throwing as far.

Like you said, there are a ton of other factors too. And the impeller/paddle is doing more than just flinging snow out, it's also moving the new snow to the center. And for a 2-stage, the augers are also sucking up power, and the transmission, etc. This is just a potentially-interesting exercise in comparing similarly-designed machines, at best.

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #16 Feb 2, 2012 10:32 am |

|

>>>You can calculate torque if you know hp and RPM Yes and no. There are general formulas for doing that I’ve seen on the net but they are not accurate. They all end up with a linear line which does not happen in reality. If you calculated that way I think you end up with a max torque at 3600 which is not right. Torque at 3600 on most of the snowblower engines will be 20-25% less at 3600 than max torque. If you took the numbers from a general linear formula and sub’ed 20-25% they would be closer. Makers would probably be using a dynamometer or something for their curves but they probably have formulas to calculate the true non-linear curve for their engines >>>So given the same torque on a 12" diameter impeller vs an 8" diameter impeller, the max tip force will be greater on the smaller-diameter, 8" impeller. It will slow down less with heavy snow. But it also won't be throwing as far. Maybe that’s way the SS’s can toss well with the lower impeller speeds compared to a 4 cycle. BTW: I picked up two types of springs this morning to replace the paper clips. Since the cases were on and half fastened I ran them again working the rev boot with the string. They worked pretty well so I scrapped putting in the springs. If I do another or have to open up the cases with the ones with clips again I’ll install a spring.

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #17 Feb 2, 2012 10:59 am |

|

>>>You can calculate torque if you know hp and RPM Yes and no. There are general formulas for doing that I’ve seen on the net but they are not accurate. They all end up with a linear line which does not happen in reality.

I don't mean this to sound argumentative, but *yes*, not yes and no  However, the caveat is that I am calculating torque at a single RPM, based on a published hp number, and am assuming that the hp is produced at the operating RPM of the machine. At a given RPM, there's no discussion about it; torque or hp can be calculated if you know the other one, and the RPM. hp = (torque * RPM) / 5252 That's the only torque formula involved in my numbers. I'm making an assumption (a reasonable one, I hope) regarding the hp and RPM. If those assumptions are OK, then the torque #'s I listed should be accurate, based on that single operating condition. You're absolutely right that this formula will show a linear hp "curve" across an RPM range, based on a constant torque. Which isn't accurate to real life. But I'm making no attempt to represent what happens at any other RPM (note that I did not attempt to show torque #'s for the higher RPM, because I have no idea what the hp & torque are when the RPM's change). I have no idea what the max torque is, which probably occurs at some lower RPM, like you said. But that wasn't what I was interested in. And, as you said, you'd need a dyno curve to really show that. Good info on the springs! If they're not needed, that might make things simpler. Do you just tug on the string and hold it while blowing? Or do you have it going to something like a little lever?

|

|

|