Abby’s Guide > Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) > Discussions > Single stage output velocity

Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) Discussions |

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Single stage output velocity

Original Message Jan 31, 2012 2:27 pm |

|

Horizontal lists don't usually post correctly so the info below..... Make...............Engine RPM,,,,,,Auger dia........Auger RPM................Velocity out ft/min Powerlite, .........4000....................7........................1550..............................2840 Murray 3ph........4100..................8 1/4....................1025..............................2213 Maco 3hp...........4100..................8 1/4....................980...............................2116 Borat....................6000.................8 1/4...................1470.............................3173 Toro 350..............4200.................8 1/2.....................xxxxx..............................xxxxx Borat, Your auger RPM was approximated from Maco's. Different belts but likely both pulley diameters are the same or very close. The estimate was 245 RPM per 1K engine RPM. It would be interesting to compare impeller bearings. Murray and Maco both have roller bearings in the drive side of the auger shaft, flange on the other. Borat your's is probably the same. I'd have to check the Toro but I think flange on both sides. The velocity out of a dual stage is 3400 to 4000 ft/min most common around 3700-3800 ft/min (that is if I am remembering those numbers right). The better brands of machines will all be at the top of the high end. Those numbers seem about right given what a Powerlite can do versus a dual stage in the back yard in conditions good for the Powerlite.

This message was modified Feb 1, 2012 by trouts2

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #2 Jan 31, 2012 3:29 pm |

|

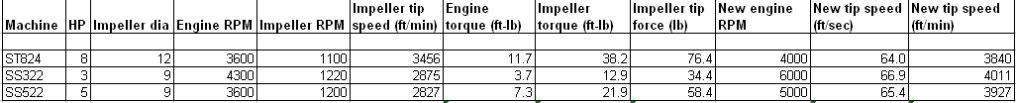

Cool idea, trouts2, I like the idea of doing a comparison. I think something may have gone funny with your impeller tip speed (velocity out) numbers, though. 2840 ft/sec is Mach 2.6. These machines are loud early in the morning, but I don't think I've noticed a sonic boom from any of mine  I pulled the specs (diameters, impeller RPM's, etc) below from the specs in the service manuals for my machines. The first is my 2-stage, second is my SS. Impeller really refers the paddle on the SS. Machine HP Impeller dia Stock Engine RPM Impeller RPM Impeller tip speed (ft/sec) New engine RPM New tip speed (ft/sec) ST824 ......8.....12................ 3600 .............................1100...................57.6.........................................4000...........................64.0 SS322.......3......9..................4300..............................1220.................. 47.9........................................ 6000...........................66.9 The 5hp SS522 (HSK850) runs the engine at 3600 RPM, the 9" augers at 1200, and has a tip speed of 47.1 ft/sec. I don't actually plan to speed up my 2-stage, I just showed a new engine RPM for giggles. Pretty interesting to see the numers. In theory, throwing straight ahead for the SS, and to the right for the 2-stage, my SS at 6000 RPM might actually throw lightweight snow further, vs the stock 2-stage. |

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #3 Feb 1, 2012 4:50 am |

|

>>>I don't think I've noticed a sonic boom from any of mine. You must be wearing earmuffs. It should be ft/min. >>>my SS at 6000 RPM might actually throw lightweight snow further, vs the stock 2-stage. For your Ariens it’s 3840 versus 4014 ft/min so a bit of an improvement. In the right snow the little guys can easily match a dual stage in distance. >>>I'm surprised the Toro has such high velocity. Me too if you’re referring to the impellers. Something is fishy with the velocity out numbers. They seem way low. Less than 3000 can’t be right can it?? If you ran a dual stage that slow it barly toss light snow. ?? >>>I'm wondering if the the Mako might have slightly different gearing than my Craftsman? Reason being that a smaller engine might not have the torque to drive the same size auger as efficiently. Good point. Do you have an online parts manual you could email? Red, 66.9 ft/sec out can’t be right. That’s 4014 ft/min. You speed is 2155 ft/min if 47.9 ft/sec is right for your impeller.

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #5 Feb 1, 2012 5:20 am |

|

>>>Are these theoretical velocity to be correlated to snow throwing distance or throughput? Right, just a Vout calc. All the factors are in play, torque, sac & etc.

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #6 Feb 1, 2012 5:29 am |

|

Red, 66.9 ft/sec out can’t be right. That’s 4014 ft/min. You speed is 2155 ft/min if 47.9 ft/sec is right for your impeller.

Are we all talking about the same thing? Output speed = velocity output = impeller (or paddle) tip speed, correct? Whether ft/sec, ft/min, or mph (or kph, for borat & co.), we're all describing the same thing. Since at least personally I'm more familiar with mph, 47.9 ft/sec is 32.6 mph, to put it more commonly-used units. My 2-stage, at 57.6 ft/sec is 39.2 mph. Those sound reasonable to me. I wouldn't expect it to be 200 mph or something. The 66.9 ft/sec number in my list was for taking my SS from 4300 RPM to 6000 RPM (boratifying it). So that's hardly a stock number, but I don't see any reason to doubt it. If the 47.9 ft/sec is correct (and it's just going through the math), then the 66.9 is just scaling up by the engine speed. Unless I'm misunderstand what you mean? And aa335, these hardly tell the whole story. Like you said, they'll give you an indication of relative throwing distances with lightweight snow (and still does not consider chute shape or any of that stuff). Snow that will still let the engine hold it's governed RPM. Once you start to bog the engine down, all bets are off. An 11hp 2-stage monster with a 50 ft/sec impeller tip speed might actually be able to maintain that tip speed, even going through 8" of wet heavy stuff. A 3hp SS even ramped up to 60 ft/sec will be just about stalled out in that same snow  I have thought in the past that it would be cool if you could crank up your auger & impeller on a 2-stage. There were a number of times with my MTD that it had the power to barrel through, say, a fluffy 4" storm. But the auger and impeller were not gathering & flinging fast enough to keep up with the forward speed I wanted. That's what we need next, folks, hydrostatic transmissions to adjust your effective gear ratio on the auger & impeller assembly

|

aa335

Joined: Nov 28, 2008

Points: 2434

![]()

|

|

Re: Single stage output velocity

Reply #7 Feb 1, 2012 5:43 am |

|

RedOctobyr, I'm pretty sure my 11hp 2 stage even at half throttle will out throw any of these high velocity SS when the snow condition is right.  If you want hydro, you have to buy a Honda or certain Husqvarna-built snowblowers (aka Craftsman). Honda even went a step further, packing dual electric motors powering the tractor section, without robbing power from the engine to throw snow ($8000 hybrid). Anyways, a fast moving 250lbs snowblower catching a broken pavement coming to a sudden stop would probably cause an enthusiastic operator to have an uncomfortable endo. And I sure don't want any more controls to change gear ratios on auger / impeller, there are already enough levelers, knobs, cranks, pedals, to keep a seasoned helicopter pilot busy. :)

This message was modified Feb 1, 2012 by aa335

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #13 Feb 1, 2012 3:17 pm |

|

hirschallan, you're probably right. And, from what trouts2 posted, the torque is already dropping off. The benefit would be that, even if you're past the torque peak, the impeller & auger will be spinning faster, and will better deal with lightweight snow. They'll fling more, and further. And as the engine loads up, it will slow down anyhow, more towards the normal operating speed. trouts2, I like that idea, of adjusting full throttle to be past 3600, for when you need just a bit more. Then just drop the throttle slightly for normal operation. Simple yet clever  I updated my numbers, to change everything to ft/min, from ft/sec. I also added a column which might begin to address aa335's point about the weight of the snow. I took the engine's RPM and rated HP, and calculated engine torque from that. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. It completely ignores power being used actually turning the augers themselves (on a 2-stage) and driving the wheels, in addition to other losses. It was more just for curiosity, and to get a relative understanding of how well the impeller/paddle would deal with heavier snow. The "Impeller tip force" would relate best to heavy snow performance, in my opinion. It's worth the paper it's printed on, as long as you don't print it   |

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #14 Feb 2, 2012 3:16 am |

|

Red, A few questions for you. >>>I took the engine's RPM and rated HP, and calculated engine torque from that. Makers usually give a Max torque at some rpm and that is usually below max torque say 24-2800 on a 3600 engine. If you take max rpm and the makers max torque that won’t be the same as the makers max torque as they spec max at some rpm lower than max. At least that’s what I’ve always seen. Also, I think hp figures are at max rpm not at max torque rpm. Since torque drops off faster and faster after max heading to 3600 and those curves vary from engine to engine then using max at 3600 can’t be done. It’s non-linear and rate of torque drop off different from engine to engine. I suppose it’s a pickle for makers. If they gave ratings at 3600 people could compare levels vs makers given max torque at 24, 25, 2600…& etc. But that would not give you max which is good to know for apps where the engine sags under load into it’s power torque range like in snowblowers. In the past I’ve looked at trying to figure out what the torque curve would be for a pushed engine and was unable to come up anything. If you have a makers published power curve then OK but most don’t give them. If the above is right then it would make the impeller torque and lb force figures iffy. But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? Just say the torque figures are off but are a rough ball park. If they are close enough then useful even if inaccurate. It’s a little more understandable to compare lbs than torque numbers. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. As mentioned before, as a side issue when thinking about this stuff it’s one thing to have the numbers but the total design implementation factors in. Once you have the get force there’s the design of the barrel, the impeller arm count, the shape of the impeller arms, shape of the bucket outlet hole, chute shape and a many more. Over the years other than chute shape a have not made much progress on understanding the other parts especially the shape of the impeller arms. It’s pretty much black magic but basic to is all is the umph has be there. Nice chart. If the chart is in excel and you don’t mind please send me a copy, trouts2@gmail.com

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #15 Feb 2, 2012 4:31 am |

|

Makers usually give a Max torque at some rpm and that is usually below max torque say 24-2800 on a 3600 engine. <snip>

If the above is right then it would make the impeller torque and lb force figures iffy. But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? Just say the torque figures are off but are a rough ball park. If they are close enough then useful even if inaccurate. It’s a little more understandable to compare lbs than torque numbers. Then factored in the torque multiplication factor from engine RPM vs impeller/paddle RPM, and also the impeller/paddle diameter. So it shows the torque on the impeller/paddle, as well as the corresponding available force at the tip of the impeller/paddle (which considers the diameter of the impeller/paddle). This is really only "useful" in comparing machines of the same type, SS or 2-stage. And "useful" is probably too strong a word. As mentioned before, as a side issue when thinking about this stuff it’s one thing to have the numbers but the total design implementation factors in. Once you have the get force there’s the design of the barrel, the impeller arm count, the shape of the impeller arms, shape of the bucket outlet hole, chute shape and a many more. Over the years other than chute shape a have not made much progress on understanding the other parts especially the shape of the impeller arms. It’s pretty much black magic but basic to is all is the umph has be there. Nice chart. If the chart is in excel and you don’t mind please send me a copy, trouts2@gmail.com You're right. However, I made no effort to use manufacturer's torque numbers (which are typically harder to find for older, hp-rated engines anyhow). If we assume that the horsepower of the engine is rated based on the operating speed (a fair assumption), then this works better. You can calculate torque if you know hp and RPM, which is what I did, for the operating speeds listed. Now, in the case of the SS322, the operating speed is 4300, not 3600. I don't know which speed the 3hp is based on. But I used the 4300, for discussion purposes. You're right that the torque is definitely a curve, so this number doesn't exactly tell the whole story. But there are so many other assumptions involved in this anyhow that it almost doesn't matter  I have come across a torque/power curve plot for at least 1 engine, I'd have to look later and see if I saved it. " But the force figure is interesting as lb’s are sort of familiar. Is that something like the force available would lift that amount one foot? "

Torque is commonly listed in ft-lb (well, lb-ft, really, but that's kind of semantics). A torque of 5 ft-lb can apply a force of 5 lbs (can lift 5 lbs), at a radius of 1 ft. Or 2.5 lbs at a radius of 2 ft. So, in the example of the ST824, the impeller has a 12" diameter, or 6" radius (0.5 ft). So the maximum force at the tip is torque/radius, or 38.2 ft-lb / 0.5 ft, or 76.4 lb.

So given the same torque on a 12" diameter impeller vs an 8" diameter impeller, the max tip force will be greater on the smaller-diameter, 8" impeller. It will slow down less with heavy snow. But it also won't be throwing as far.

Like you said, there are a ton of other factors too. And the impeller/paddle is doing more than just flinging snow out, it's also moving the new snow to the center. And for a 2-stage, the augers are also sucking up power, and the transmission, etc. This is just a potentially-interesting exercise in comparing similarly-designed machines, at best.

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #16 Feb 2, 2012 10:32 am |

|

>>>You can calculate torque if you know hp and RPM Yes and no. There are general formulas for doing that I’ve seen on the net but they are not accurate. They all end up with a linear line which does not happen in reality. If you calculated that way I think you end up with a max torque at 3600 which is not right. Torque at 3600 on most of the snowblower engines will be 20-25% less at 3600 than max torque. If you took the numbers from a general linear formula and sub’ed 20-25% they would be closer. Makers would probably be using a dynamometer or something for their curves but they probably have formulas to calculate the true non-linear curve for their engines >>>So given the same torque on a 12" diameter impeller vs an 8" diameter impeller, the max tip force will be greater on the smaller-diameter, 8" impeller. It will slow down less with heavy snow. But it also won't be throwing as far. Maybe that’s way the SS’s can toss well with the lower impeller speeds compared to a 4 cycle. BTW: I picked up two types of springs this morning to replace the paper clips. Since the cases were on and half fastened I ran them again working the rev boot with the string. They worked pretty well so I scrapped putting in the springs. If I do another or have to open up the cases with the ones with clips again I’ll install a spring.

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #17 Feb 2, 2012 10:59 am |

|

>>>You can calculate torque if you know hp and RPM Yes and no. There are general formulas for doing that I’ve seen on the net but they are not accurate. They all end up with a linear line which does not happen in reality.

I don't mean this to sound argumentative, but *yes*, not yes and no  However, the caveat is that I am calculating torque at a single RPM, based on a published hp number, and am assuming that the hp is produced at the operating RPM of the machine. At a given RPM, there's no discussion about it; torque or hp can be calculated if you know the other one, and the RPM. hp = (torque * RPM) / 5252 That's the only torque formula involved in my numbers. I'm making an assumption (a reasonable one, I hope) regarding the hp and RPM. If those assumptions are OK, then the torque #'s I listed should be accurate, based on that single operating condition. You're absolutely right that this formula will show a linear hp "curve" across an RPM range, based on a constant torque. Which isn't accurate to real life. But I'm making no attempt to represent what happens at any other RPM (note that I did not attempt to show torque #'s for the higher RPM, because I have no idea what the hp & torque are when the RPM's change). I have no idea what the max torque is, which probably occurs at some lower RPM, like you said. But that wasn't what I was interested in. And, as you said, you'd need a dyno curve to really show that. Good info on the springs! If they're not needed, that might make things simpler. Do you just tug on the string and hold it while blowing? Or do you have it going to something like a little lever?

|

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #20 Feb 2, 2012 2:04 pm |

|

Guilty as charged. And I love the Turbo Encabulator videos, great stuff.

This is a great site for a bunch of different Tecumseh engine info:

http://www.smallenginesuppliers.com/html/engine-specs/tecumseh-engine-specs.html

I won't insert the pics here, but they have scans of the spec sheets for a number of different engines. Including, but not limited to, the HSK600, the HSK845 (sorry, no 850), and HM80 (which seems to be a summer version of the venerable HMSK80).

These actually show charts like dnyo plots. They appear to show torque, and (I can't read it) possibly maximum horsepower in addition to what might be continuous operating horsepower. I had the most luck trying to "read" the HM80 version.

HSK600:

http://www.smallenginesuppliers.com/html/engine-specs/tecumseh/features/hsk600.jpg

HSK845:

http://www.smallenginesuppliers.com/html/engine-specs/tecumseh/features/hsk845.jpg

HM80:

http://www.smallenginesuppliers.com/html/engine-specs/tecumseh/features/hm80.jpg

I found it interesting that, for the HSK600, different RPM's are spec'd for different manufacturers. 4300-4500, so my current 4600 really isn't much outside the suggested range (my service manual shows 4300). Also the HSK600 pic lists 32:1 for oil (50:1 for the HSK845), but my gas cap & service manual says 50:1.

It's a shame that these images show much interesting/useful info, but that the quality is poor enough that much of it can't be read. If anyone finds better copies somewhere else, I'd be curious to find out where.

|

borat

Joined: Nov 9, 2007

Points: 2692

![]()

|

|

Re: Single stage output velocity

Reply #21 Feb 2, 2012 3:22 pm |

|

From reading the specifications, the KSK840, 845, 850 engines are very similar but have certain components that have different part nos. The power output is as follows: 840= 4h.p., 845= 4.5, 850= 5, 870= 7 h.p. The HSK870 is apparently very similar to the 850 although, when comparing part numbers, I see some differences. These are the most glaring differences. HSK850 HSK870 Crankshaft 290684 290675

Carburetor 640313 640300

Muffler 390318A 390343

All other relevant components share the same part numbers including the cylinder assembly, crank bearings, connecting rod kit etc.

I also noted that the above component numbers varied between the 840 and 850. Got to wonder what going on?

Are the above parts different from each other or, is it just a numbers change? If the actual components are different, it's not hard to understand why Tecumseh went out of business. Way too much parts differentiation between very similar engines. And that's just their HSK 800 series.

I guess it's possible that on the 870, the crank might have been lightened, a larger main jet and freer flowing muffler put on to allow it to rev quicker/faster. However, there's no change in the cylinder assemblies thus no changes to porting. I can see those changes plus additional rpm bringing up the h.p. to 7 in the 870. I've yet to see anything with an HSK870 engine in it.

Here are a couple links if anyone wants to check the parts numbers. Note that the first link prices are much better than Partstree.

http://www.absolutemower.com/pages/OemParts#%2fTecumseh_Power_Company%2fHSK870-8701A%2fEngine_Parts_List%2fHSK870-8701A%2fEHSK841HSK8XX8701A-EN

http://www.partstree.com/parts/?lc=tecumseh&mn=HSK850-8317C&dn=EHSK841HSK8XX8317C-EN

Comments?

This message was modified Feb 2, 2012 by borat

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #24 Feb 3, 2012 5:17 am |

|

RedOctobyr: “At a given RPM” OK, got it, reasonable and valid. One hp & rpm getting one torque value. No cheating…. The charts are hard to follow but can be zoomed in go get the values. All you need is one and can guess the others as they just increment. The top right is FT LBS (the solid lines across) Lower left HP The top right Newton Meters (the dashed lines across) The bottom right HP in kW The bottom RPM The top line is torque. The middle line is Maximum B.H.P & kW The bottom line is Recommended Maximum operating B.H.P and kW Red, “If anyone finds better copies somewhere else, I'd be curious to find out where. Below for a readable PDF with many engines. Has HSK600, HSK845 but no HSK850. http://th.manualwebsite.com/pdf/engine_and_accessories_2001.pdf On the chart you posted. How did you that? It looks like a jpg. It looks to clear to be a screen capture. Did you save the XL as a .pdf and convert it to .jpg? Borat, “Way too much parts differentiation between very similar engines”. Not sure exactly which component numbers but… Sears would order a cover and choke special for their machines. That would boot those numbers and the final engine assembly. In some cases Sears would order a lesser crank for their engines for a price break. Ariens would require small mods at times. MTD would have a PTO extension on the cam. Murray used double pulleys with stepped cranks ends again causing number changes. There might be 50-100 variations on a HSSK80 in a year. A few times on a rebuild the bore and piston values did not match the Tecumseh spec for that engine. Possibly the engine was a dash model ordered on special. ?? Red, “Unless the 850's muffler was adjusted to allow better power production at higher RPMs”? A manf requesting a muffler change is not uncommon. Bill, “Do they say what RPM they reach those HP numbers at”? The final RPM value in the charts Red posted are all 3600. In the manual above the spec’s use 3200 and 3600. I think the 32’s are lawnmower engines.

|

trouts2

Location: Marlboro MA

Joined: Dec 7, 2007

Points: 1328

![]()

|

|

Re: Single stage output velocity

Reply #25 Feb 3, 2012 12:16 pm |

|

Red, More comments about the Amazon type tach... There are scads available with that case type. Some variations are replaceable batter or sealed case, with and without a ground wire, and various arrangemens of wire ends like clips or no clips. Mine were low end and listed as replaceable battery but the case was sealed. They did not come with a ground wire but I installed ground wires in them. No end clips but I installed those also. The readings as I mentioned were not that reliable until the ground wire was put in. The reading update was ok but no that fast. Today I installed one on a single stage. I only attached the sense lead without ground to check it out and the readings were excellent with a much faster update on rpm changes. ?? It was never that fast before even with ground attached. The difference is probably a better signal to the RPM gauge for what ever reason like cowling or less noisy plug..?? Works like a charm mounted to the carry handle with tape. |

RedOctobyr

Location: Lowell area, MA

Joined: Nov 4, 2011

Points: 282

![]()

|

|

Re: Single stage output velocity

Reply #27 Feb 3, 2012 1:50 pm |

|

trouts2, it's somewhat interesting (to me, at least): The last few times I've used my digital tach/hourmeter, I've had some issues with the screen suddenly going from RPM to "11111" then "2222"..... counting up towards "99999". I can't figure out exactly what's causing it. It will usually go back to an RPM by 4 or 5. I *presume* it's caused by an iffy signal to the meter. Maybe it's from the RPM changing? As I recall, the engine isn't necessarily hunting while it's doing this. Usually, when I've been using it recently, I've been doing it quick-and-dirty. Mine has no connector on the spark plug end (wraps around the wire a few times), then it has a round connector you put under an engine bolt. To make things simpler, I've been clipping an alligator lead onto the ground connector, and clipping the other end onto a cooling fin. Perhaps that's part of the cause. I've never actually tried disconnecting the ground entirely.

borat, what you're describing sounds like what I've heard called a Vibratach? I've heard good things about them, but never seen one used. I bought my tach/hour meter for about $30 a few years ago, because it did both functions, could be mounted so you can keep an eye on the RPMs while using the machine, etc. But what you're describing does admittedly sound interesting. With an eye towards my own potential use for something like that, can they be used on chainsaws? And what RPM do they reach? The saw is supposed to be 13,000.

http://www.machovec.com/quest/vibratach.htm

|

|

|