Abby’s Guide > Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) > Discussions > John Deere 1130 SE

Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) Discussions |

|

Clay

Location: Wis

Joined: Dec 2, 2008

Points: 111

![]()

|

|

John Deere 1130 SE

Original Message Jan 7, 2009 8:07 am |

|

I did a search and found a few references to this machine but no answers. Any one have one of these? 15.5 snow max engine, heated hand grips, 30" wide. I can't find a listing for auger diameter or impeller diameter. I called John Deere and the guy that was suppose to be the snow thrower expert didn't know either. What is the Easy Steer drive system? The literature says: Easy Steer® drive system giving continuous power to both wheels and auto speed adjustment Is it similar to the Ariens auto differential? I've heard that the units are built by B&S which translates to Simplicity. They do have cast iron gear cases like the Simplicity. The chute control is different than the simplicity and so is the turning method so they are not exactly the same. I'm trying to compare the Simplicity L1530E to the JD 1130SE. Any help would be appreciated. Rick |

lanningjw

Location: MINNEAPOLIS, MINNESOTA

Joined: Oct 7, 2009

Points: 29

![]()

|

|

Re: John Deere 1130 SE

Reply #215 Dec 27, 2009 4:41 am |

|

The Easy steer really helped me to be more effective, because I can go down the middle of the drive way, and then do a 180 tight turn while staying under power and continue blowing snow. The 1130 has a big powerful engine, the blower weights in at 250 lbs and seems to be able to dig down into the snow because of the balance of the wheels and the front end. I am happy and so are the folks that live around me. I did raise the skids with the paint stir stick, but it seems to be to high and leaves alot of snow on the driveway, any advise?

This message was modified Dec 27, 2009 by lanningjw

|

Swoods

I love all power equipment from lawn mowers to snow blowers. My favorite pieces of equipment are 2 cycle Lawn Boys.

Location: Elburn, IL

Joined: Nov 20, 2009

Points: 65

![]()

|

|

Re: John Deere 1130 SE

Reply #216 Dec 27, 2009 5:02 am |

|

As far as adjusting height, I used a piece of steel I had in the garage (about 2/3 thickness of a paint stirrer), under the auger housing next to the height adjuster. You may just be able to sand down one end of your paint stick to around 2/3 thickness and it should be about right. At this height, I leave a pretty clean path on my asphalt driveway. The one thing I wish it had was some sort of a skid towards the front of the auger housing. When I go down the sidewalk, the machine bangs into the uneven sections. It probably wouldn't be too hard to fashion some sort of a skid or something. By the way, when I checked the voltage of my headlight wire, it was at full throttle. This gave me the 13.3 volts. I would assume that full throttle would be the highest voltage, but I could be wrong. I can check it later and rev the engine up and down to see if it gets higher. I did end up mounting some rubber between the headlight bracket and the machine last night. I had some really thick rubber from an old tractor inner-tube. I cut two pieces the same size as the bracket (doubled them up for extra thickness) and drilled a hole in the center for the bracket bolt. I'll try to get another headlight today to see how it works.

Sean Woods

|

ccginmn

Location: Saint Michael, MN

Joined: Jan 19, 2009

Points: 5

![]()

|

|

Re: John Deere 1130 SE

Reply #218 Dec 28, 2009 10:34 am |

|

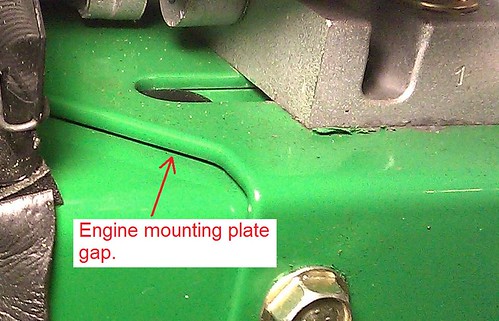

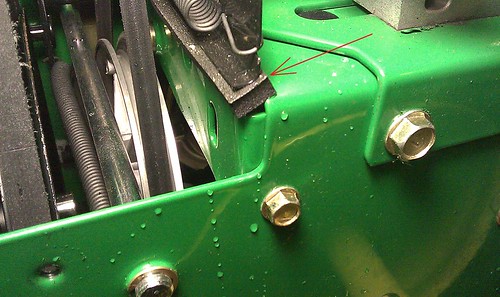

I'm happy to finally report that my 1130SE disc drive is no longer intermittently slipping and I've had plenty of snow to test it many times. I had to seal items a little more to get it to this point. If you can keep water off the drive disc the tires will push like crazy. This view is inside the transmission box directly below the engine. When snow gets on the engine it melts, runs down the sides and then underneath the engine and under the engine mounting plate. After that it runs through the open holes and into the transmission. I've actually caught it and know for sure these need to be sealed. I filled most of the holes with silicone but missed two dime size holes. I didn't think these would be a problem as they weren't open all the way through. However, I definitely saw water and one of these is directly above the rubber disc drive wheel. This picture shows one of the dime size holes with no silicone. The hole is covered by the engine mounting plate but it still has enough space for water to get through.  ... and here it is filled with silicone (top red arrow). Make sure you fill the other dime size hole (lower red arrow) and any other open holes (yellow arrows). One open hole is a potential problem, but as you can see there are many holes.  This is just one example of several open areas where water can get under the engine. You can see a puddle of water to the right of the open gap.  There are many places where water can get under the engine or engine mounting plate and run into the transmission  Another large gap.  In this picture you can see silicone under the engine. The silicone was applied from under the transmission and is coming up through the hole.  When water gets on the aluminum drive disc (yellow arrow) the rubber drive wheel slips. Eventually the spinning aluminum disc slings the water off and the drive no longer slips. Here you can see the water that was slung from the aluminum disc (red arrows).  I truly don't know if the next item is required, but I will explain what I did and why. This view is of the foam fix used by Deere to supposedly correct the slipping problem. Unfortunately in my case the foam doesn't fit very tight on the left side of the machine. Water that gets near the foam can still run under it.  Here you can see two very small trails of water that made it's way under the foam. The water then drops directly onto the aluminum drive pulley and gets slung potentially causing a slipping problem.  I added foam as seen below. I extended the foam down each side to make sure water can't get on the pulley when the machine is tilted. The side foam will be covered by the plastic belt cover.  Here is Deere's foam and the foam that I added. It seems to be water tight.  I've had snow all over the snowblower including the engine. Everything has been working great now.  Merry Christmas!!!

Catt,

This is the best tutorial I've seen to ensure this slipping problem is fixed. Briggs & Stratton should be paying you to audit their engineering dept. I'm definately going to add your suggestions to my 1130 this summer. I just got my blower back from John Deere with both updates. Randy at Schaber & Sons told me that B & S sent the updates out this past summer. I personally think it should have been a recall. Anyways, it worked great on the last snowfall so I'm happy again. In fact, I have a new appreciation for decent equipment in general (read below). Yesterday I tried my Dad's three-year old MTD Yardman 8hp snowblower ($800) out on 12" of snow. Granted this isn't an apples to apples comparison as my John Deere 1130 is 10.5 hp and costs $400 more. The MTD's wheels began slipping after about ten minutes. It progressively got worse until it only worked about half the time. After violently shaking it and letting it sit for 30 seconds, the wheels would engage for five more minutes before I had to repeat over and over again. The chute had a tremendous amount of snow that came out of the backside and the adjustment is down by your knees. Also, it only threw the snow 8 - 12 feet. I was blowing with a good wind so this meant I started on one side of the driveway and worked my way to the other side. Everything I threw on the first three passes landed on the other side of the driveway meaning I had to blow the same snow twice. My little brother just purchased a 5 year-old Simplicity 924 for $600. He also has twice the blower as compared to the MTD, although he doesn't have the bells and whistles of the 1130. My point is that it is WAY better to buy a decent used machine than a new piece of junk.

|

|

|