I'm happy to finally report that my 1130SE disc drive is no longer intermittently slipping and I've had plenty of snow to test it many times. I had to seal items a little more to get it to this point. If you can keep water off the drive disc the tires will push like crazy.

This view is inside the transmission box directly below the engine. When snow gets on the engine it melts, runs down the sides and then underneath the engine and under the engine mounting plate. After that it runs through the open holes and into the transmission. I've actually caught it and know for sure these need to be sealed. I filled most of the holes with silicone but missed two dime size holes. I didn't think these would be a problem as they weren't open all the way through. However, I definitely saw water and one of these is directly above the rubber disc drive wheel. This picture shows one of the dime size holes with no silicone. The hole is covered by the engine mounting plate but it still has enough space for water to get through.

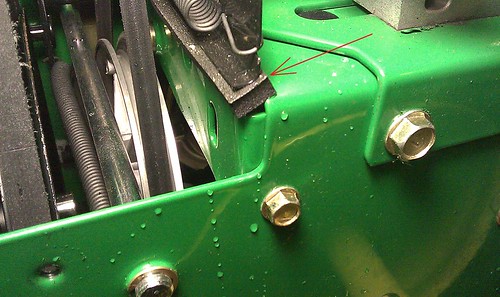

... and here it is filled with silicone (top red arrow). Make sure you fill the other dime size hole (lower red arrow) and any other open holes (yellow arrows). One open hole is a potential problem, but as you can see there are many holes.

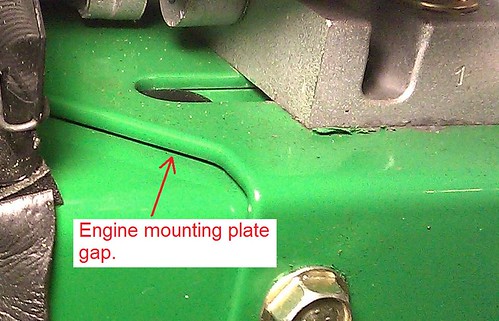

This is just one example of several open areas where water can get under the engine. You can see a puddle of water to the right of the open gap.

There are many places where water can get under the engine or engine mounting plate and run into the transmission

Another large gap.

In this picture you can see silicone under the engine. The silicone was applied from under the transmission and is coming up through the hole.

When water gets on the aluminum drive disc (yellow arrow) the rubber drive wheel slips. Eventually the spinning aluminum disc slings the water off and the drive no longer slips. Here you can see the water that was slung from the aluminum disc (red arrows).

I truly don't know if the next item is required, but I will explain what I did and why.

This view is of the foam fix used by Deere to supposedly correct the slipping problem. Unfortunately in my case the foam doesn't fit very tight on the left side of the machine. Water that gets near the foam can still run under it.

Here you can see two very small trails of water that made it's way under the foam. The water then drops directly onto the aluminum drive pulley and gets slung potentially causing a slipping problem.

I added foam as seen below. I extended the foam down each side to make sure water can't get on the pulley when the machine is tilted. The side foam will be covered by the plastic belt cover.

Here is Deere's foam and the foam that I added. It seems to be water tight.

I've had snow all over the snowblower including the engine. Everything has been working great now.

Merry Christmas!!!

This message was modified Dec 26, 2009 by Catt