Abby’s Guide > Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) > Discussions > Help with Carburetor Cleaning

Outdoor Power Equipment (Lawn Mowers, Snow Blowers, Chain Saws and more) Discussions |

|

donjag

i've gone to find myself,if i'm here when you arrive,keep me here until i get back.

Location: menasha,wisconsin

Joined: Apr 24, 2007

Points: 142

![]()

|

|

Re: Help with Carburetor Cleaning

Reply #12 Feb 16, 2008 3:18 am |

|

you can maybe try using a easy out,you drill into the broken screw,put this threaded thing(the easy out)into the hole and turn it out.i find there is NOTHING easy about this.or if you have enough meat sticking out,you might try a vice grips put on very carefully and slowly try turning out,but be careful,if you use the vicegrips there is a good chance you will only get one try at it.good luck.

|

nibbler

Joined: Mar 4, 2004

Points: 751

![]()

|

|

Re: Help with Carburetor Cleaning

Reply #14 Feb 16, 2008 2:30 pm |

|

Thanks for the info. Unfortunately the screw in question is a 6-32 x 1/2" so its kind of small to start with. I'm not sure why it broke off, it didn't feel like I was forcing it but with a screw that small I might not know my own strength  . I have used so called screw extractors before and this thing is too small for the smallest that I have. There is a bit of a nub and I do have a Dremel tool so I'll try the cut a slot technique. The only problem is the weather forecast is for freezing rain so I have to wait for sunnier times. I tried running the engine and there was no more hesitation however it did start to race at one point and the bowl seems to leak when I turn the engine off. I closed the fuel cutoff and ran the engine dry so the dripping didn't occur but I have a hunch I have to open it up and look at the float and inlet valve assembly. This sure is a learning experience. |

borat

Joined: Nov 9, 2007

Points: 2692

![]()

|

|

Re: Help with Carburetor Cleaning

Reply #17 Mar 14, 2008 7:37 pm |

|

Not to be a smart ass but you had me laughing for a while there. I admire your perseverance and patience. However,personally, I'd have tossed that carb into orbit and bought a new one by now. Good luck to you and thanks for the updates. |

nibbler

Joined: Mar 4, 2004

Points: 751

![]()

|

|

Re: Help with Carburetor Cleaning

Reply #18 Mar 15, 2008 9:13 pm |

|

No probs. As to why I haven't gotten a new one: - This is the first time I have done a carburetor cleaning, its a learning experience and therefore perseverance is the name of the game, I have to learn from my mistakes;

- I an cheap

. . - This is for the "spare" snowblower, I can afford to have it out of service while I "play".

As far as I can see most have my problems are from inexperience and a fair bit of dumb luck. I am learning and thats the main reason for posting, so people can learn from my mistakes, giving then a good laugh is an added bonus.

This message was modified Mar 15, 2008 by nibbler

|

Location: CAN

Joined:

Points: 638

![]()

|

|

Re: Help with Carburetor Cleaning

Reply #19 Mar 15, 2008 9:34 pm |

|

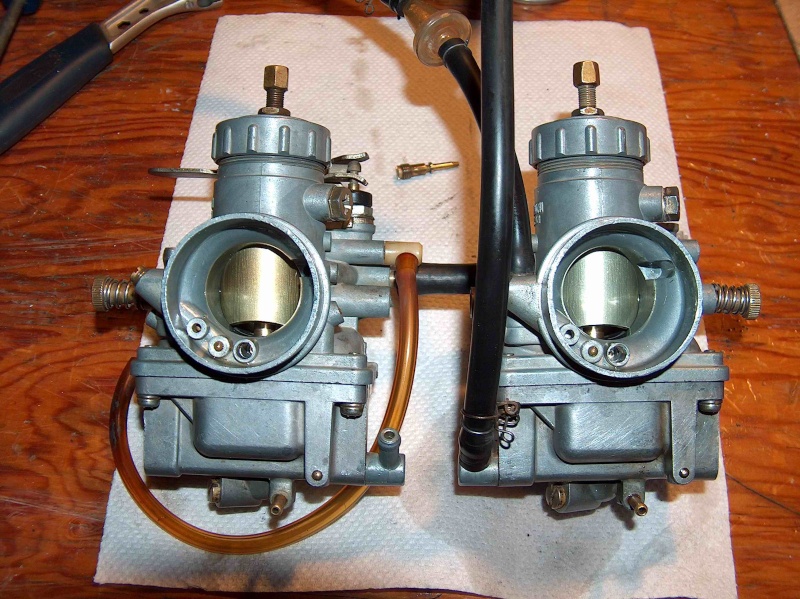

I just finished cleaning and rebuilding my two Mikunis. Lots of little parts to clean and replace (in this case). One picture shows the shiny new replacement parts and the not so clean original parts. The other shot is of the 32 year old carbs all cleaned up, re-assembled and pretty much ready to go..   Borat, I remember in 1973, I owned a Kawasaki semi-trail 90cc, that cames a with a mikunis carburator, very good quality, they really never gum out, well to say the truth, the engine never stops running hehehehe I was 14 years old you imagine, gas at that time was 49.9 cents a gallon :)) Yep Mikunis the only thing is on to 2 stroke engine vibration is present and going down and up pit sand the mikunis got easy disajusted, You are using 2 mikunis parallel :)) keep a flat screwdriver under seat you may need it, buy the way you are doing a pretty nice clean job on it, congradulation

This message was modified Mar 15, 2008 by Denis

|

|

|